Sandy Trex Railing Materials and Installation

Sandy Trex is a leading manufacturer of top-quality railing materials that not only enhance the beauty of your outdoor space but also ensure long-lasting durability. If you’re considering upgrading your railing system, it’s essential to understand the features and benefits of Sandy Trex railing materials. Additionally, having a comprehensive guide to the installation process, troubleshooting common issues, and understanding the sustainability and environmental impact of these railings will help you make an informed decision. Let’s delve into the world of Sandy Trex railing materials and installation to discover the possibilities they offer.

Understanding Sandy Trex Railing Materials

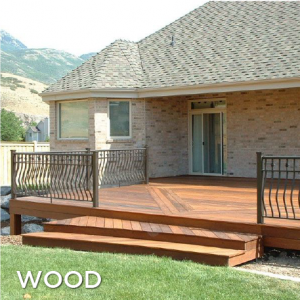

Before diving into the specifics, it’s important to grasp the fundamentals of Sandy Trex railing materials. These materials are known for their exceptional strength and resistance to harsh weather conditions. Moreover, they come in a variety of styles and colors, allowing you to choose the perfect match for your design aesthetic.

Key Features of Sandy Trex Railing Materials

Sandy Trex railing materials are engineered with several key features that set them apart from the competition:

- Superior Strength: The materials are manufactured using advanced composite technology, making them stronger and more durable compared to traditional railing materials.

- Weather Resistance: Sandy Trex railings are designed to withstand the harshest weather conditions, including intense sunlight, heavy rains, and even snow.

- Low Maintenance: Unlike wood railings that require regular sanding, painting, and staining, Sandy Trex railings are virtually maintenance-free. They only require occasional cleaning to keep them looking their best.

- Customizable Options: With a wide range of colors, styles, and accessories, Sandy Trex railings offer limitless possibilities to create a railing system that reflects your unique taste and suits your outdoor space perfectly.

Benefits of Using Sandy Trex Railing Materials

Choosing Sandy Trex railing materials for your project can bring you a multitude of benefits:

- Enhanced Safety: Sandy Trex railings provide a secure barrier that prevents accidents and ensures the safety of your family and guests.

- Longevity: These railings are built to last, meaning you won’t have to worry about frequent replacements or repairs.

- Aesthetics: The wide array of design options allows you to create a railing system that complements your outdoor space, elevating its visual appeal.

- Increased Property Value: By investing in Sandy Trex railings, you not only enhance the beauty and safety of your home but also increase its market value.

A Comprehensive Guide to Sandy Trex Railing Installation

Installing your Sandy Trex railing system is a straightforward process that can be accomplished with the help of basic tools and a little know-how. Let’s break down the steps involved:

Pre-Installation Preparations

Prior to starting the installation, it is important to gather all the necessary tools and materials. Additionally, ensure that you have thoroughly read and understood the manufacturer’s instructions to ensure a successful installation. Preparing the site by cleaning and clearing any obstructions will provide a clean canvas for your new railing system.

Step-by-Step Installation Process

The installation of Sandy Trex railings can be divided into several key steps:

- Attach the Post Base: Start by attaching the post base to the surface, be it wood, concrete, or any other suitable material.

- Install the Posts: Once the post bases are securely fastened, it’s time to install the posts using the provided hardware.

- Attach the Rails: After the posts are in place, attach the rails to create the horizontal support structure of your railing system.

- Secure the Balusters: With the rails installed, you can then secure the balusters at regular intervals to provide safety and an appealing visual design.

- Finishing Touches: Finally, add any desired accessories and make any necessary adjustments to ensure your railing system is sturdy and visually appealing.

Post-Installation Care and Maintenance

While Sandy Trex railings require minimal maintenance, they still benefit from regular care to keep them looking their best. Regularly cleaning them with mild soap and water will remove any dirt or debris, while gentle scrubbing can tackle stubborn stains. By following these simple maintenance practices, your railing system will maintain its functionality and beauty for years to come.

Troubleshooting Common Issues with Sandy Trex Railings

Occasionally, you may encounter some issues with your Sandy Trex railing system. Let’s explore some common problems and their effective solutions:

Identifying Common Problems

Common issues with Sandy Trex railings include loose or wobbly posts, cracked balusters, or fading of color. Identifying these problems early on will ensure timely intervention and prevent further damage.

Effective Solutions for Common Issues

To address these problems effectively, consider reinforcing loose posts with additional hardware, replacing cracked balusters with new ones, and implementing regular cleaning and maintenance routines to prevent color fading. If you encounter more complex issues, it is advisable to consult a professional installer for guidance.

Sustainability and Environmental Impact of Sandy Trex Railings

As concerns about environmental impact grow, it’s crucial to consider the sustainability of the materials we choose. Sandy Trex railings are designed with sustainability in mind:

Material Composition and Sustainability

Sandy Trex railings are made from a mixture of reclaimed wood fibers and recycled plastic. By utilizing these recycled materials, Sandy Trex contributes to reducing the demand for virgin resources, helping to preserve the environment.

Environmental Impact of Sandy Trex Railings

In addition to their sustainable composition, Sandy Trex railings have a minimal ecological footprint. Unlike traditional wood railings that contribute to deforestation, Sandy Trex railings are an eco-friendly choice that helps protect our forests and natural resources.

Cost Analysis of Sandy Trex Railing Materials and Installation

Understanding the cost implications of using Sandy Trex railing materials and the associated installation expenses is essential when planning your budget. Let’s break it down:

Pricing of Sandy Trex Railing Materials

The cost of Sandy Trex railing materials may vary based on factors such as the style, color, and quantity required for your project. It is advisable to consult with your local supplier to obtain accurate pricing information.

Installation Costs and Considerations

When it comes to installation costs, several factors come into play, including the complexity of the project, labor costs, and any additional accessories or customization involved. While DIY installation is possible, it may require specialized tools and skills. Hiring a professional installer ensures a seamless and efficient installation process.

Long-Term Cost Effectiveness of Sandy Trex Railings

Though Sandy Trex railings may have a higher upfront cost compared to traditional wood railings, their long-term cost-effectiveness is unrivaled. With minimal maintenance requirements and exceptional durability, Sandy Trex railings save you money on repairs and replacements in the long run.

In conclusion, Sandy Trex railing materials offer a wide range of benefits for homeowners seeking durability, versatility, and sustainability. Understanding the key features, installation process, troubleshooting common issues, and the eco-friendly nature of these railings empowers you to make the best decision for your outdoor space. With Sandy Trex, you can create a stunning railing system that not only enhances the aesthetics of your home but also stands the test of time.